August 09, 2018

From Forest to Flat-Pack: How Tylko Shelves Come to Life

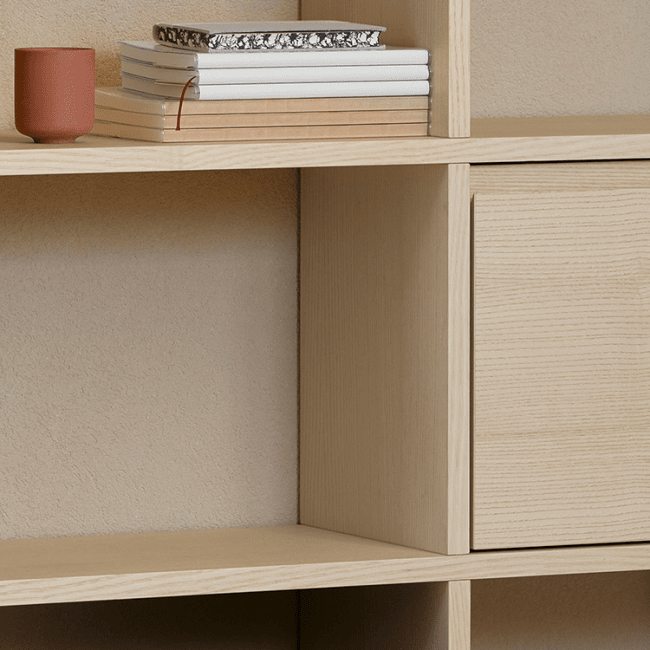

We take a look at the lifecycle of a shelf… from tree trunk to totally bespoke.

We spoke with Senior Product Development Engineer Zbyszek Latuszkiewicz about why Tylko works with plywood, how our shelves go from concept to creation, and all the little production details in between. Be warned: you had no idea the process was so fascinating.

What are the secrets of the plywood used in Tylko furniture?

We place great emphasis on the quality of this raw material. Our plywood is made from wood harvested in Northern and Northeastern Europe. The climate there is harsh but great for forest growth. It guarantees that the birch have small, very dense and homogeneous growth rings – which means very few defects like knots, or signs of insect feeding or diseases. The strong winters make the northern hardwood beautiful – as well as incredibly strong and durable!

So harsh weather makes stronger wood? Interesting! Actually making the plywood is a fascinating process too, right?

Plywood was invented to answer the issue of acquiring wood in a form that would not be prone to damage. Building anything from solid wood is a constant battle against the cylindrical shape of trees. Timber shrinks unevenly as humidity changes – it twists and bends. But someone once got an idea to peel the entire trunk using a long knife to cut a spiral line – to make a very long paper-thin ribbon. This strip can then be cut into sheets and placed like layers of lasagne. This sandwich of wood and glue is then put in a press, firmly squeezed and heated to harden the glue which makes large, reproducible flat sheets with properties exceeding those of solid wood.

And that’s why plywood the best material for making furniture?

Yes! It has exceptionally high flexural, tensile, compressive and shear strengths in the plane of the board. Much higher than other wood-based products such as MDF, particle board or even solid wood. This translates directly into the load bearing capacity of Tylko shelves – they are perfect for storing heavy objects such as books without the risk of visible sagging. And, plywood perfectly holds and maintains all nuts and connectors – there is no shifting – all of our pieces of furniture can be disassembled and reassembled multiple times without risking damage. You can boldly say that Tylko shelves are pieces of furniture that will last a lifetime!

What about plywood’s aesthetics?

Plywood has high aesthetic properties – we don’t need to hide its edge underneath a plastic guard. On the contrary! The edge constitutes an important and original visual accent of our furniture. We love it so much, we hand-oil it.

I know that the plywood you use in production has to meet more than quality requirements.

Yes – much more! We have to make sure that Tylko products that land in customers’ homes are 100% safe. The plywood can’t contain or emit any substances into the environment that can pose a risk to health. We exclusively use materials with appropriate certificates, tested by reputable institutes – not just for the plywood, but also the coatings, glues and laminates.

We also only purchase boards produced using wood obtained in a sustainable manner and new trees are planted in place of the ones we cut down, which means that Tylko’s furniture doesn’t come at the cost of natural ecosystems. Our plywood suppliers also care that the wood does not come from habitats of rare and threatened species of animals.

How does the plywood go from a piece of generic board to a finished piece of Tylko furniture?

Our factory receives finished plywood boards of the highest possible quality. They’re then covered on both sides with a protective layer of high-quality laminate. Then the boards are cut into customer-specific furniture parts which are then processed, finished, equipped with connectors and fittings, and packaged. At each stage of production, a quality control takes place – for both the materials and the results of each individual technical operation. We also conduct random audits of entire finished pieces of furniture, checking whether everything is made according to plan. Then it’s sent in our trademark orange packaging directly to a waiting customer! Even our packaging is bespoke! For each piece of furniture, the shape of its package is automatically designed by a special algorithm, then cut out from cardboard by an automatic machine – all so the package will perfectly fit the bookshelf, just like the bookshelf perfectly fits the customer’s space!

What is your role in the production process?

I am responsible for ensuring that new functions of furniture do not make assembly and usability of shelves difficult or unpleasant or dangerous. Each new idea for an upgrade or different function is a huge challenge. It must be soundly thought-out and tested before we decide to offer it to our customers. My role is to design technical solutions and implement them for production. I’m also responsible for making prototypes and perform all sorts of tests – I contract some of them to our factory and even perform some of them myself. The company’s growth means continuously perfecting existing solutions, and my work involves many hours of designing, manual labor, visits to the factory and hundreds of drawings and sketches.

From your perspective, what is the most interesting in all these processes?

Tylko furniture is not a closed project, it is a living organism that constantly grows and evolves. Working to create new solutions is a bit like travelling into the unknown and exploring new lands. I’m curious myself what the next year of working on Tylko shelves will bring. We have several very interesting ideas up our sleeves, and I believe that we will surprise our customers and the entire furniture market many more times!

*

Zbyszek Latuszkiewicz

Graduated from the Faculty of Wood Technology at the Warsaw University of Life Sciences. He began his professional career as a student – first as a designer of very unique furniture and storefronts for an international corporation, then as a work coordinator for a team of engineers. Furniture engineering and technologies of production and processing of wood-based boards, including plywood, are his hobby and passion. In private, he runs a blog where he presents his individual projects.